| Technology is introduced: |

|

|

| Process principle: |

|

After the exhaust gas comes out from the turbine, it enters into the exhaust mixing pipe. A urea measuring injection device is installed on the mixing pipe, and the urea water solution is sprayed into the pipe. After the hydrolysis and pyrolysis reaction of urea at high temperature, NH3 is generated. In general, the consumption of 100L of fuel oil will consume 5L of liquid urea solution.  Ecosail-s series internal combustion engine emission control product line is widely applicable to generator sets and engine test benches; Diesel engine/gas electromechanical plant; Landfill gas, kitchen waste landfill gas power plant; Distributed energy stations; Marine diesel engines and so on. |

| Techunical advwantage: |

|

Ecosail-s series has rich experience in denitrification system integration with advanced denitrification catalyst research and development and production technology

High temperature denitrification catalyst for distributed energy

• Extremely wide operating temperature :160-600℃

• Low NOx emission concentration :20mg/Nm³

• Meet the stringent emission requirements of Euro 6

• Efficient system integration and Internet of Things technology

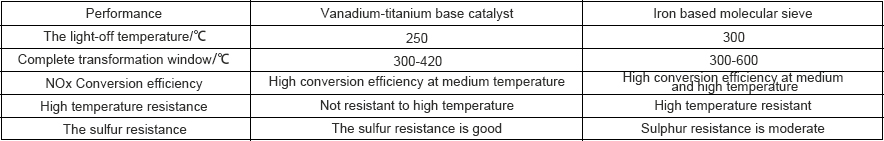

As a clean and efficient use of natural gas, the distributed energy system of natural gas is also an effective measure to improve air quality. However, the energy system is generally installed near the users, so the emission of pollutants has become the focus of attention of the users. Because natural gas is cleaner and has a lower sulfur content, sulfur dioxide and dust are often discharged under the standard. Nitrogen oxides (NOX), mainly of thermal type, are the primary controlled pollutants. Distributed energy flue gas of natural gas has the characteristics of high direct exhaust temperature (450~550℃) and low exhaust temperature (<200℃) after energy cascade utilization, which limits the application of traditional vanadium titan-based denitrification catalyst. Zeolite catalyst has the characteristics of wide reactivity temperature window and stable high temperature performance, so it has become the choice of distributed energy denitration system.

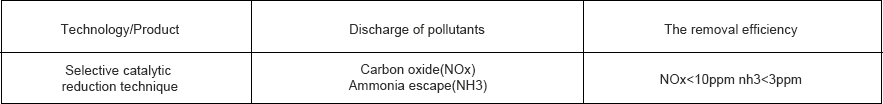

Our company has three production technologies and products of the following three catalysts:

|

| System composition: |

|

|

| System composition: |

|

1. Urea pump

Adjustable ratio up to 1:30, higher than traditional

The metering pump is about 30 times higher;

· High measurement accuracy;

· Smooth output, continuous high precision measurement;

· Automatic flow adjustment;

· Integrated flow measurement.

2. Vegetable spray nozzle

Atomized particles are very fine. Average diameter is 40-60 microns, ensuring 100% evaporation;

· Adjustable ratio up to 10:1.

· Good anti-clogging performance and low gas consumption;

· Life span up to 3-5 years.

3. Urea tank

Equipped with stirring and electric heating function, can accelerate the dissolution of urea;

Constant temperature electric heating function, to avoid the storage of urea solution due to the low ambient temperature, urea precipitation crystallization blockage pipeline;

4. Other system components

SCR reactor

Urea injection control cabinet;

Measuring tank;

Exhaust temperature sensor;

NOx sensor;

Urea spray gun;

Urea solution preparation system;

Storage tanks;

Air compressor;

By-pass system

|